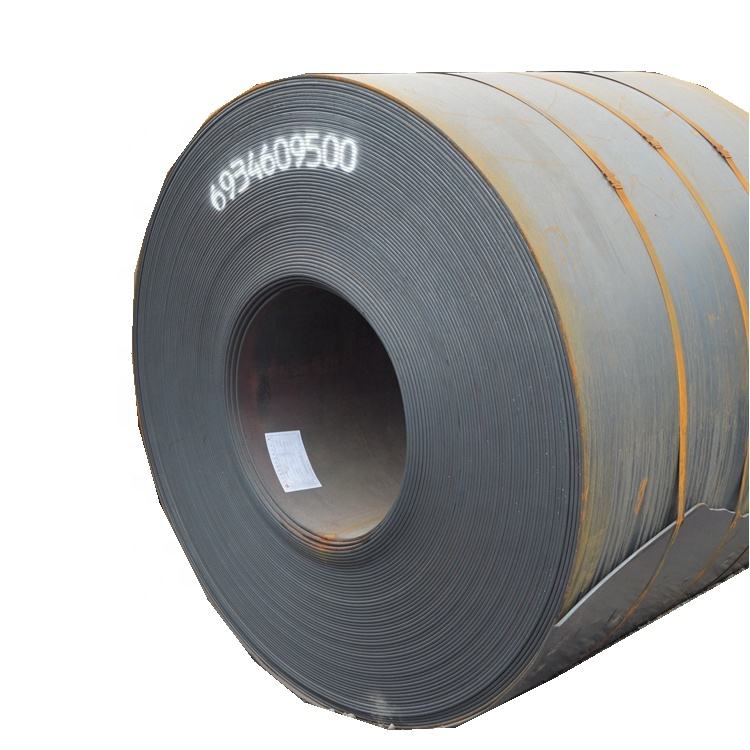

Ss400, Q235, Q345 Sphc Black Steel Carbon Steel Coil Iron Steel Metal Hr Hot Rolled Steel Coil

Hot-rolled steet/coil from finishing the last hot steel strip mill out through laminar flow cooling to the set temperature, which consists of the winder coil, steel coil after cooling, according to the different needs of users, with different finishing line (flat, straightening, transverse or longitudinal cutting, inspection, weighing, packaging and logo, etc.) and become a steel plate, flat roll and longitudinal cutting steel strip products. Because hot rolled steel products have high strength, good toughness, easy processing and good weldability and other excellent properties, it is widely used in shipbuilding, automobile, bridge, construction, machinery, pressure vessel and other manufacturing industries.

| Grade | Rank | Chemical Composition( %) | ||||

| Q215 | C | Mn | Si | S | P | |

| A | 0.09~0.15 | 0.25~0.55 | ≤0.3 | ≤0.05 | ≤0.045 | |

| B | ≤0.045 | |||||

| Q235 | A | 0.14~0.22 | 0.30~0.65 | ≤0.3 | ≤0.05 | ≤0.045 |

| B | 0.12~0.20 | 0.30~0.70 | ≤0.045 | |||

| C | ≤0.18 | 0.35~0.80 | - | ≤0.04 | ≤0.04 | |

| D | ≤0.17 | ≤0.035 | ≤0.035 | |||

| Q255 | A | 0.18~0.28 | 0.40~0.70 | ≤0.3 | ≤0.05 | ≤0.045 |

| B | ≤0.045 | |||||

| Q275 | 0.28~0.38 | 0.50~0.80 | ≤0.35 | ≤0.05 | ≤0.045 | |

Carbon steel is a common type of steel that is an alloy of iron and carbon. It has a higher carbon content, lower melting point and greater durability compared to stainless steel.

Carbon steel is the most widely used engineering and construction material for industrial applications on a large scale, including marine structures, power plants, transportation, chemical processing and petroleum production and refining

Δ Hot rolled material is annealing in cold rolled annealing furnace and after pickling in acid.

Δ All mill rolls are grinded on precision grinding machine with proper chamfering after first shift operation.

Δ All sheets are pickled in different tanks and sheets are dried on brush roll machine before dispatch.

Δ These sheets are again annealing then sent to straighten machine for straightening and pickling in acid and send for packing according to size and quality.

Δ Inspection is done at various stages. By experience staff keeping proper control overall internal process via rolling, annealing, pickling, treatment of waste etc.